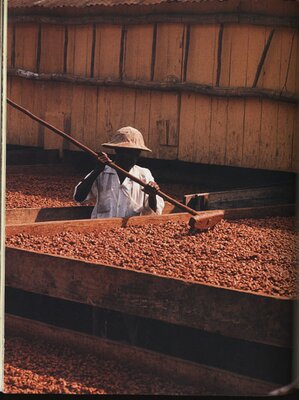

Drying and Manufacturing

Following fermentation, beans are spread on sunny platforms to dry. There they are raked or turned several times a day for 3 to 5 days. Sometimes drying is accelerated with oil or wood burning rotary driers, but sun drying produces the best flavor.

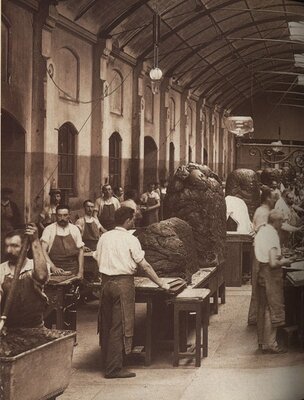

When the bags of fermented and dried cacao beans arrive at a chocolate factory, the beans are first put through a sieve and cleaned to remove foreign material. They are then roasted in large rotating ovens, which brings out their flavor and aroma, and shrinks the beans away from their hulls. The roasted beans are inserted into a winnowing machine, which cracks them and blows the hulls away, leaving what are called nibs. If different varieties of cacao are to be blended, they are mixed together now before the nibs move on to a series of rollers which grind them to a thick paste—the cocoa mass or liquor. At this point, the cocoa mass can be made into cocoa powder or chocolate for eating.